COB vs. BOX Packaging Transceiver Optics: A Comprehensive Comparison

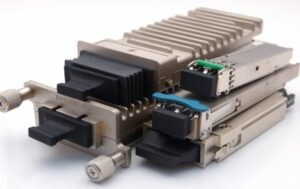

The rapid expansion of bandwidth demands in data centers has fueled the need for higher data rates and density optical interconnects. High-speed optical transceivers, essential components in optical links, are gaining popularity in data center applications. In this guide, we explore two primary packaging technologies: COB (Chip-on-Board) and BOX (Airtight Package) for high-speed optical transceivers.

In this article, you’ll discover:

- What BOX Packaging Transceiver is

- What COB (Chip on Board) Packaging Transceiver is

- The key differences between COB vs. BOX Packaging Transceiver

- FAQs about COB vs. BOX Packaging Transceiver

Understanding COB (Chip on Board) Packaging Transceiver

COB is a packaging method that directly attaches a chip to a PCB board. An optoelectronic chip is bonded to the board using silver-containing epoxy resin adhesive. The connection is made through wire bonding, and the chip is sealed with epoxy or silicone resin. COB technology is widely used in various industries, especially high-speed telecommunications. In the optical transceiver industry, COB is prevalent in applications like 25G SFP28 SR, 40G QSFP+ SR4, 100G QSFP+ SR4, and more.

Understanding BOX (Airtight Package) Packaging Transceiver

BOX packaging involves encapsulating the optical chip in a metal box filled with inert gas. This protects the optical components from the environment and enhances heat dissipation. The optical path is isolated using an optical window. BOX packaging is used in long-reach transceivers such as 25G SFP28 LR, 40G QSFP+ LR4, 100G QSFP28 LR4, and others.

COB vs. BOX Packaging Transceiver: A Comparative Analysis

Let’s compare COB and BOX packaging transceiver optics in various aspects:

- Pricing: COB is generally priced lower than BOX.

- Reliability: BOX packaging offers higher reliability compared to COB.

- Suitable Transceiver Types: COB is suitable for SR optics, PSM4 optics, and AOC. BOX is used for LR optics, LR4 optics, ER4 optics, and ZR4 optics.

- Size: COB packaging is smaller, while BOX packaging is larger.

- Application Scenarios: COB is commonly used in data centers, 10G/40G/100G Ethernet. BOX is utilized in telecom, data centers, 10G/40G/100G Ethernet, and 5G wireless networks.

- Manufacturing Complexity: COB has medium manufacturing complexity, while BOX has high complexity.

FAQs about COB vs. BOX Packaging Transceiver

- Optcore offers both COB and BOX packaging transceivers.

- COB is ideal for short-reach applications, while BOX is suited for long-reach scenarios.

- Your choice between COB and BOX depends on your specific needs.

- BOX and COB transceivers have the same electrical interface but aren’t interchangeable for telecom applications.

- COB packaging is reliable and mature.

Conclusion: Making the Right Choice

The COB vs. BOX packaging transceiver optics comparison highlights the differences in performance, use cases, and prices. COB offers better electrical and thermal performance, while BOX provides stable optical and electrical performance. When selecting between COB and BOX packaging, consider your specific application needs to make the best decision.